Precision Meets Power: What is Laser Engraving?

In the world of manufacturing and DIY crafting, few technologies have bridged the gap between industrial utility and creative artistry as seamlessly as laser engraving. Whether it’s a personalized leather wallet, a serial number on a jet engine component, or an intricate wooden wedding invitation, laser engraving is the "magic wand" behind the scenes.

In the world of manufacturing and DIY crafting, few technologies have bridged the gap between industrial utility and creative artistry as seamlessly as laser engraving. Whether it’s a personalized leather wallet, a serial number on a jet engine component, or an intricate wooden wedding invitation, laser engraving is the "magic wand" behind the scenes.

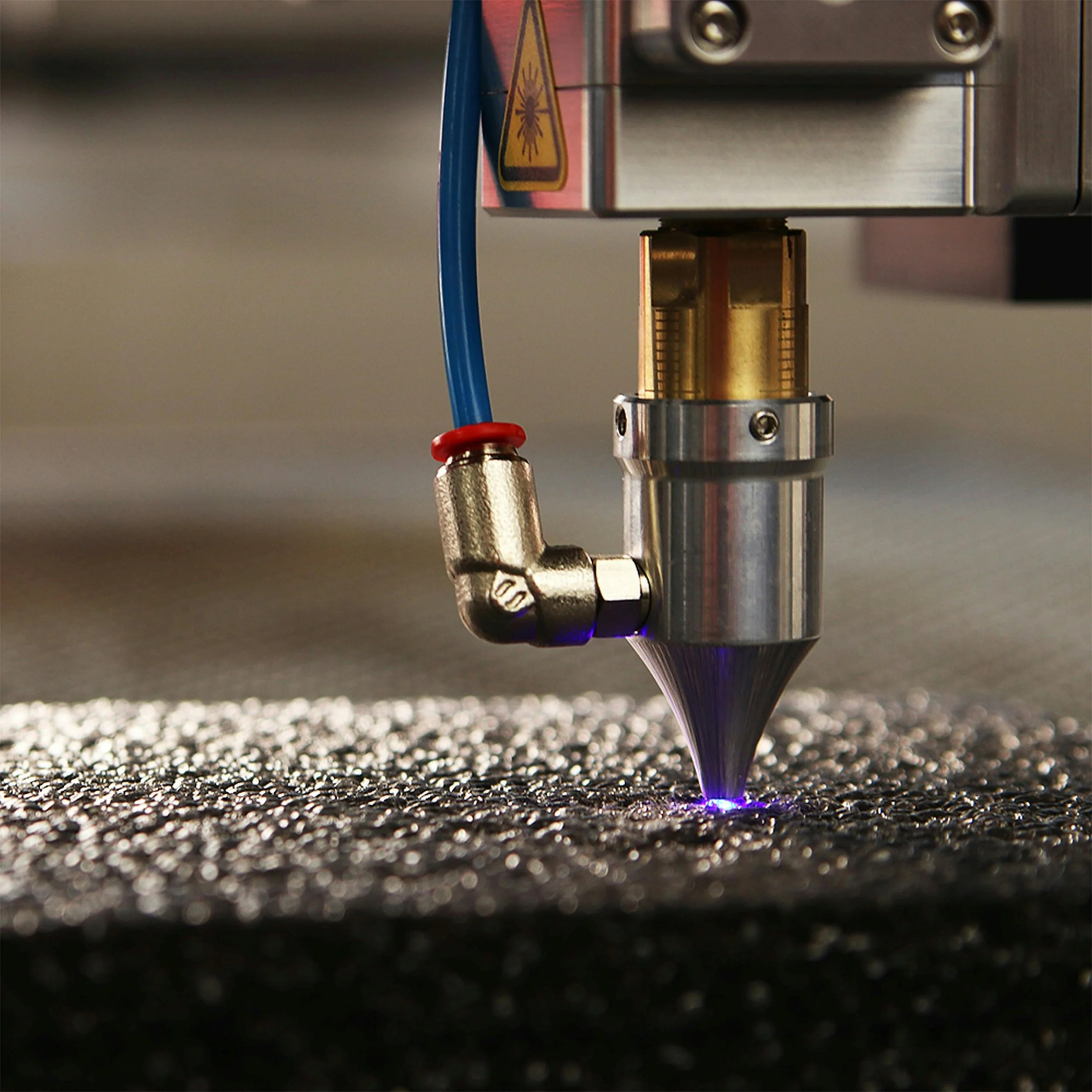

But what exactly is it? At its core, laser engraving is a subtractive manufacturing process that uses a high-powered light beam to physically remove material from a surface, leaving a permanent, deep, and highly precise mark.

How the Magic Happens: Sublimation

Unlike traditional engraving, which uses a sharp metal tool to gouge out a surface, laser engraving never touches the material. Instead, it uses a concentrated beam of light—the laser—to deliver massive amounts of energy to a localized area.

This heat is so intense that the material doesn’t just melt; it undergoes sublimation. This means the solid material turns directly into a gas (vaporization) almost instantly. The result is a clean, crisp crevice in the material that creates a tactile, permanent design.

Laser Engraving vs. Etching: What’s the Difference?

These terms are often used interchangeably, but in the industry, they refer to different depths:

Laser Engraving: Digs deep into the material (typically up to 0.5mm). It’s incredibly durable and resistant to wear, making it ideal for items exposed to harsh conditions.

Laser Etching: A subset of White Dog engraving that only affects the top "micro-surface." It melts the surface to create high contrast rather than a deep cavity.

Laser Marking: Usually refers to a chemical change (such as oxidation) on the surface that leaves a dark mark without removing any material.

What Materials Can You Engrave?

The versatility of this technology depends on the type of laser being used.

CO2 Lasers: The "workhorses" for organic materials like wood, acrylic, glass, leather, and paper.

Fiber Lasers: These operate at different wavelengths, making them ideal for "tougher" materials like stainless steel, aluminum, brass, and carbon fiber.

Wood

Home decor, signs, photosCO2

Metal

Tool identification, jewelryFiber

Acrylic

Awards, LED signs, keychainsCO2

Leather

Wallets, patches, beltsCO2

Why Use Laser Engraving?

Extreme Precision: Lasers can reproduce designs with microscopic detail that would be impossible to achieve by hand.

Speed: Once a digital design is uploaded, a laser can complete a complex engraving in seconds or minutes.

Non-Contact: Because nothing physical touches the piece, there is no risk of the material warping or the "tool" wearing out over time.

Permanence: Unlike ink or stickers, an engraving won’t peel, fade, or wash off.

Contact Us

From industrial traceability to high-end customization, laser engraving is a cornerstone of modern design. It’s the perfect marriage of high-tech physics and human creativity.

Get an engraving quote today by calling us at 972)848-7790 or click here to connect with us online.

The Real Value of Custom Engraving: Cost vs. Reward

When you’re looking to turn a standard gift into a cherished keepsake, the question inevitably arises: How much does engraving actually cost? And more importantly, is it worth the extra investment?

When you’re looking to turn a standard gift into a cherished keepsake, the question inevitably arises: How much does engraving actually cost? And more importantly, is it worth the extra investment?

At White Dog Engraving, we believe that understanding the "why" behind the price helps you make the best choice for your project.

What Determines the Price?

Engraving isn't a one-size-fits-all service. The cost typically ranges from $5 to $25 per item for standard projects, though high-end custom work can go higher. Several factors influence the final quote:

Material: Harder materials like stainless steel or glass often require more time and specialized laser settings compared to softer woods or leather.

Design Complexity: A simple name in a standard font is quick and affordable. Intricate logos, custom handwriting, or detailed photos require more setup time and precision.

Quantity: Ordering in bulk (like for wedding favors or corporate branding) often lowers the price per piece significantly.

Is It Worth It?

The short answer is yes, and here is why:

1. Emotional Impact A plain cutting board is a kitchen tool; a cutting board engraved with Grandma’s handwritten recipe is an heirloom. Engraving adds a layer of thoughtfulness that transforms a "product" into a "memory."

2. Durability and Permanence: Unlike vinyl stickers or screen printing, laser engraving is permanent. It won’t peel, fade, or wash away. Whether it’s a dog tag or a commemorative plaque, the message lasts a lifetime.

3. Professional Branding For businesses, engraved logos signal quality. It tells your clients that you don't just "do business"—you care about the details. It elevates your brand from ordinary to premium.

Ready to start your next project? Whether you have a specific design in mind or need a little inspiration, we’re here to help.

[Click here to request a custom quote] or contact us today at (972) 848-7790 to speak with our team about your project.

Why You Need a Dallas Texas Engraver for Your Next Project

In a city as big and vibrant as Dallas, standing out is everything. Whether you’re a business owner looking to leave a lasting impression on a client or a resident searching for the perfect anniversary gift, generic off-the-shelf items rarely cut it.

In a city as big and vibrant as Dallas, standing out is everything. Whether you’re a business owner looking to leave a lasting impression on a client or a resident searching for the perfect anniversary gift, generic off-the-shelf items rarely cut it.

That is where the art of engraving comes in. Choosing a professional Dallas Texas Engraver isn't just about putting a name on a cup; it’s about transforming an ordinary object into a permanent legacy. From the sleek office buildings of Downtown to the creative hubs in Deep Ellum, custom engraving is the secret weapon for those who value quality and detail.

Why Choose Local for Your Engraving Needs?

When you search for a Dallas Texas Engraver, you aren’t just looking for a machine—you’re looking for a partner who understands the local pace and style. Local engravers offer several distinct advantages:

Quick Turnaround: No waiting weeks for shipping from overseas. Local shops understand the "everything is bigger (and faster) in Texas" mentality.

Material Expertise: Whether it’s Texas-sourced wood, industrial-grade metals, or delicate glassware, a local pro knows how to handle the materials specific to your project.

Face-to-Face Collaboration: There’s no substitute for seeing a proof in person or discussing a custom design with an expert who can tell you exactly how a laser will react to your specific item.

Endless Possibilities for Business and Home

What can a Dallas Texas Engraver actually do for you? The list is longer than the line at a popular BBQ joint on a Saturday:

Corporate Branding: Move beyond plastic pens. Think laser-etched leather portfolios, stainless steel tumblers with your logo, or high-end acrylic awards for your top performers.

Special Occasions: Personalized wedding gifts, engraved wine bottles for housewarmings, or custom-etched picture frames to capture DFW memories.

Industrial Marking: For local manufacturers, permanent serialization and part marking are essential for compliance and branding.

Make Your Mark with White Dog Engraving

If you’re ready to take your project to the next level, look no further than the experts at White Dog Engraving. As a premier DFW engraving company, they combine state-of-the-art technology with a personal touch that is uniquely Texan.

From custom promotional products that get your brand noticed to one-of-a-kind gifts that will be cherished for a lifetime, White Dog Engraving is the trusted name for quality and precision in North Texas.

Ready to get started? Contact us today to discuss your next project. Whether you have a single heirloom or a bulk corporate order, they have the tools and talent to make your vision a reality.

Precision Meets Purpose: Where to Fit Engraving in Your 2026 Marketing Plans

Thinking about making engraving part of your 2026 marketing plans? You’re making a smart choice! Click here.

As we head into 2026, the marketing landscape is shifting away from "mass-produced" and toward "meaningfully personal." In an era of digital saturation and AI-generated content, consumers are hungry for the tangible—something they can hold, keep, and connect with.

For businesses looking to stand out, custom engraving is no longer just a "nice-to-have" add-on; it is a strategic tool for building brand loyalty. Here is how to integrate engraving into your 2026 marketing strategy.

1. Elevated Corporate Gifting

The days of "swag" are over. In 2026, the trend is "kept-not-tossed" merchandise. Instead of plastic pens with printed logos that rub off, companies are opting for high-quality, laser-engraved items like:

Insulated Drinkware: Premium matte-finish tumblers with permanent, precision-etched logos.

Tech Accessories: Engraved wireless charging pads or power banks for hybrid workers.

Executive Kits: Personalized notebooks or leather-bound journals that feel like a curated gift rather than a generic giveaway.

2. The "Human Touch" in a Digital World

One of the biggest illustration and design trends for 2026 is the "Human-Touch" aesthetic. Brands are purposefully turning to traditional crafts to deliver a deeper connection. Engraving offers a multi-sensory experience—the weight of a glass decanter, the texture of engraved wood, and the permanence of a message. By using engraving for your VIP client rewards or milestone trophies, you signal that your brand values craftsmanship and longevity.

3. Sustainability as a Standard

Sustainability is a non-negotiable marketing pillar for 2026. Unlike chemical inks or plastic stickers, laser engraving is an eco-friendly process. It requires no solvents and produces zero ink waste. Fitting engraving into your plans allows you to market your brand as environmentally conscious, especially when paired with sustainable materials like bamboo, FSC-certified wood, or recycled stainless steel.

4. Hyper-Personalization for Events

If you are hosting events in 2026, consider on-site live engraving. It transforms a simple activation into a memorable experience. Watching a name or custom quote appear on a product in real time creates a "wow" moment that attendees will share on social media, giving your brand organic digital reach.

Making the Cut

Engraving bridges the gap between your digital identity and the physical world. Whether it’s through QR codes permanently etched onto retail signage or personalized "self-care" kits for employees, the goal is the same: to create a lasting impression.

As you finalize your 2026 budgets, look past the ephemeral. Invest in the permanent. Invest in engraving. Learn more about our services by contacting us at (972)848-7790 or click here to connect with us online.

More Than Just a Mark: Why Custom Engraving is the Ultimate Gift

In a world of mass-produced products and last-minute digital gift cards, there is something truly special about an item that was made specifically for one person. Whether it’s a name, a significant date, or a heartfelt quote, custom engraving transforms an ordinary object into a lifelong keepsake.

In a world of mass-produced products and last-minute digital gift cards, there is something truly special about an item that was made specifically for one person. Whether it’s a name, a significant date, or a heartfelt quote, custom engraving transforms an ordinary object into a lifelong keepsake.

At White Dog Engraving, we believe that every mark tells a story. Here is why custom engraving remains the gold standard for thoughtful gifting and professional branding.

The Power of Personalization

When you give someone a personalized gift, you’re saying more than just "Happy Birthday" or "Congratulations." You’re showing that you took the extra time to plan, design, and create something unique.

Engraving adds a layer of sentiment that can’t be replicated. A simple wooden cutting board becomes a family heirloom when etched with a grandmother’s secret recipe. A stainless steel tumbler becomes a daily source of motivation when it bears a personal mantra. By choosing to engrave, you aren’t just giving a gift—you’re creating a memory.

Durability That Lasts a Lifetime

One of the most significant advantages of engraving over printing or vinyl stickers is its permanence. While ink can fade and stickers can peel, an engraving is physically etched into the material.

Whether it’s glass, wood, leather, or metal, our engraving process ensures that your message stands the test of time. It’s weather-resistant, wear-resistant, and designed to look just as sharp years from now as it does the day it leaves our shop.

Elevate Your Business Brand

Custom engraving isn’t just for gifts; it’s a powerful tool for businesses. High-quality, laser-engraved corporate gifts—like insulated bottles, notebooks, or keychains—leave a lasting impression on clients and employees alike.

In a competitive market, branding is everything. Engraving your logo onto premium materials signals professionalism, attention to detail, and a commitment to quality. It’s a "silent salesperson" that stays on a client’s desk or in their hand for years to come.

Versatility Across All Materials

Modern engraving technology allows us to work with an incredible variety of surfaces. Some of our most popular requests include:

Metal: From rugged dog tags and multi-tools to elegant watches and flasks.

Wood: Custom signs, coasters, and kitchenware that add a rustic, personal touch to any home.

Glass & Acrylic: Sophisticated awards, glassware, and decorative ornaments.

Leather: Personalized wallets, journals, and patches that age beautifully.

Ready to Create Something Unique?

Whether you are looking for the perfect wedding gift, a way to honor a beloved pet, or promotional items for your growing business, we are here to help bring your vision to life. At White Dog Engraving, we pride ourselves on precision, quality, and a personal touch that you won't find anywhere else.

Contact White Dog Engraving today for all of your engraving needs! Click here to browse our services or reach out for a custom quote. Let’s make your next gift unforgettable!

A Beginner’s Guide to Foil Stamping: Adding Sparkle to Your Designs

Want to elevate your printed materials from nice to absolutely stunning? Enter foil stamping! This technique is a fantastic way to add a premium, tactile, and visually striking element to everything from business cards and invitations to book covers and packaging.

Want to elevate your printed materials from nice to absolutely stunning? Enter foil stamping! This technique is a fantastic way to add a premium, tactile, and visually striking element to everything from business cards and invitations to book covers and packaging.

What is Foil Stamping?

Foil stamping, also known as hot foil stamping, is a process where a pre-dried ink or metallic foil is applied to a surface. Unlike traditional printing, which uses wet ink, this method uses entirely dry ink.

Here’s the simple mechanism:

A custom metal die (like a stamp, usually made of magnesium, copper, or brass) is created with the exact design you want to foil.

The die is heated up.

The heated die is pressed onto the material with a sheet of metallic foil placed in between.

The heat and pressure cause the foil to release from its carrier sheet and bond permanently to the material, leaving behind a crisp, shiny impression.

Why Choose Foil Stamping?

Unmatched Shine: Foil offers a metallic luster that regular metallic ink cannot replicate. It catches the light beautifully, immediately drawing attention.

Tactile Quality: The slight indentation (debossing) created by the press adds an extra dimension of feel.

Versatility: Beyond traditional gold and silver, foils come in a dazzling array of colors, matte finishes, pearlescent effects, and even holographic patterns.

Tips for Beginners

Consider the Material: Foil looks best on smooth, sturdy White Dog paper stocks (100lb cover weight or higher). Highly textured paper can sometimes interfere with a clean transfer.

Keep it Bold: Fine lines and tiny text can be tricky to read. Opt for thicker lines, medium-to-large font sizes, and simpler graphics for the best results.

Check Your "Foil Safe Area": If you're combining foil with regular ink printing, ensure there's a small buffer (a few millimeters) between the two to prevent alignment issues.

Foil stamping is a powerful tool to make your designs feel luxurious and memorable. It’s an investment that truly pays off in perceived value!

Learn more about the services that we can offer you by calling us at (972)848-7790 or click here to connect with us online.

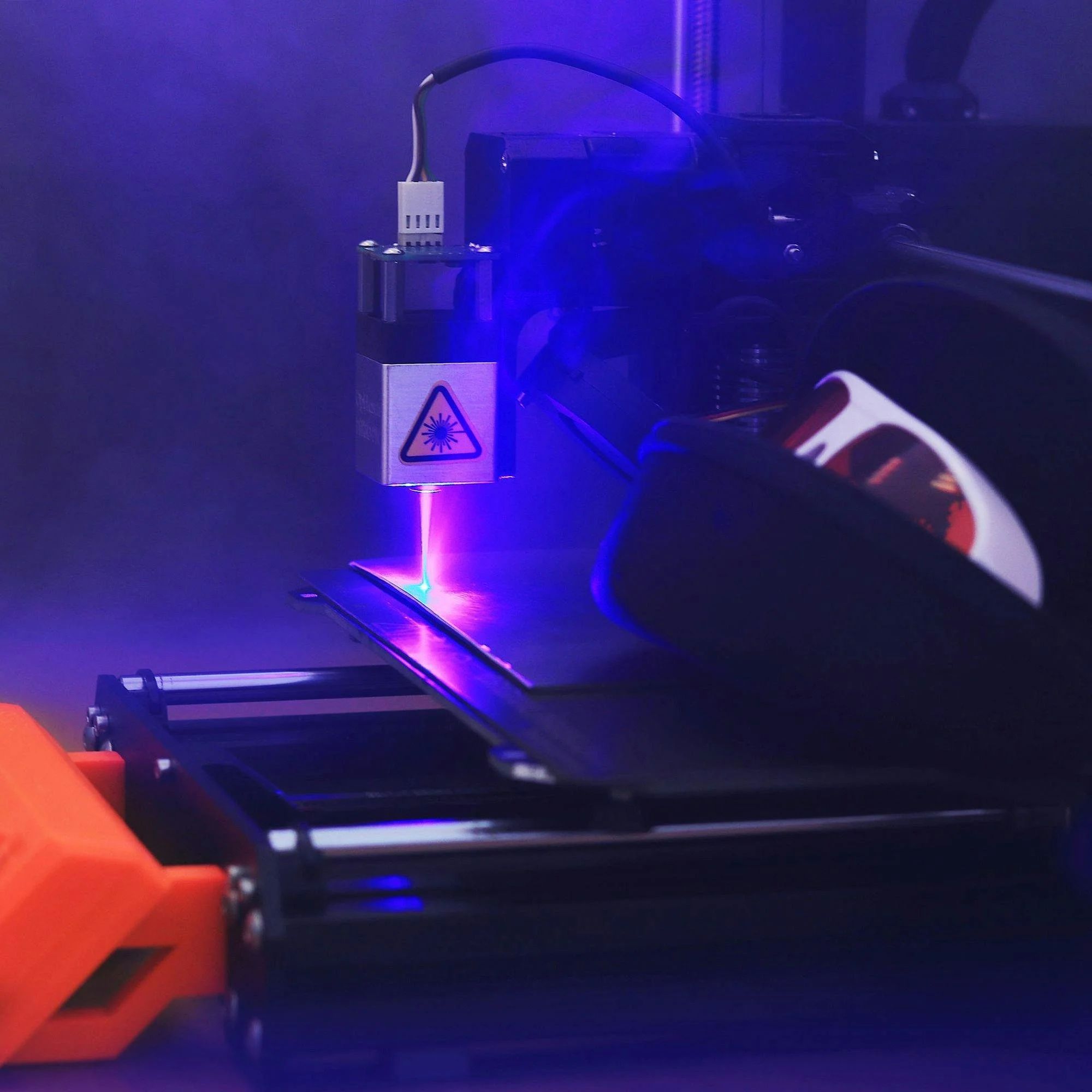

Best Laser Cutters & Engravers for 2025–2026

From hobbyist diode to production-ready CO₂ and fiber systems, 2025 highlighted top picks. Choose by material, workspace, safety, and support.

From hobbyist diode to production-ready CO₂ and fiber systems, 2025 highlighted top picks. Choose by material, workspace, safety, and support.

Best overall CO₂ — xTool P2

Best overall CO₂ cutter: If you are looking for a powerful and accurate CO₂ cutter for materials like wood or acrylic, the xTool P2 offers an effective balance of speed, pass-through capability, and intuitive software. It is a strong choice for dedicated makers and small shops.

Best prosumer — Glowforge (Pro / Aura)

Best prosumer: Glowforge provides one of the most user-friendly turnkey experiences, with refined software, an active community, and dependable presets for quick, clean cuts. It is well-suited for those who prioritize convenience over deep customization.

Best diode (budget & hobby) — Atomstack family

Best diode: For beginners or crafters on a budget, Atomstack's compact diode models (Swift, A5) deliver excellent resolution and value. The newer Kraft series introduces dual-laser capability for more demanding cutting, which benefits small projects and rapid prototyping.

Best industrial / professional — Trotec Speedy

Best industrial/professional: For White Dog businesses where uptime, support, and precision are critical, Trotec’s Speedy series continues to set the benchmark. These machines are fast, durable, and geared for high-volume production in woodworking, signage, and manufacturing.

Best value for shops — OMTech / Polar series

Best value for shops: For cost-sensitive businesses that need larger work areas and adequate power, OMTech’s Polar series offers a strong price-to-feature ratio. It is a common recommendation for smaller or growing shops.

Final tip

Match the laser type (diode, CO₂, fiber) to the materials, check ventilation and safety, and weigh the warranty and service before buying. Want a quick buyer’s checklist or comparison table? I can make one.

Learn more about the engraving services that we can offer you by calling us at (972)848-7790 or click here to connect with us online.

Top Five Most Thoughtful Engraved Gifts for Christmas

When the holidays drift in like a snow-soft whisper, the most meaningful gifts tend to be the ones touched by personalization. Engraved items carry a quiet gravity—each one a small constellation of memory, shaped in metal, wood, or glass. If you’re hoping to give something that feels both intimate and timeless, here are five engraved gifts that shine brightest beneath the Christmas tree.

When the holidays drift in like a snow-soft whisper, the most meaningful gifts tend to be the ones touched by personalization. Engraved items carry a quiet gravity—each one a small constellation of memory, shaped in metal, wood, or glass. If you’re hoping to give something that feels both intimate and timeless, here are five engraved gifts that shine brightest beneath the Christmas tree. ✨

1. Custom Engraved Ornaments

A personalized ornament turns the tree into a storybook. Whether it marks a baby’s first Christmas, a new home, or a beloved family name, engraved ornaments become yearly companions—tiny heirlooms that return with every December.

2. Personalized Cutting Boards

For the home chef, an engraved cutting board is both an art piece and a workhorse. Add a family recipe, a special date, or a short message, and suddenly this humble kitchen tool becomes a keepsake for the future, steeped in the aromas of tradition.

3. Engraved Bracelets or Necklaces

Jewelry already carries a whisper of sentiment, but White Dog engraving a name, set of coordinates, or small phrase transforms it into a story. It’s a wearable reminder of connection—something that rests on the skin and warms with meaning.

4. Custom Engraved Knives or Multi-Tools

For the practical person on your list, an engraved pocket knife or multi-tool feels equal parts useful and personal. It’s the kind of gift that gets tucked into pockets, backpacks, and glove compartments—an everyday companion stamped with a message from you.

5. Engraved Picture Frames

A frame captures a moment, but an engraved frame enriches it. Adding dates, names, or short dedications turns a simple image into a chapter of family lore.

Engraved gifts don’t just celebrate the season—they tether memories to physical objects, creating little anchors of joy that last far beyond the holidays

Get a custom engraving quote today by calling us at (972) 848-7790 or click here to connect with us online.

Can You Engrave Canvas?

Fiber and UV lasers are leading technologies for marking, engraving, and cutting materials. Both offer high precision and efficiency, but operate on different principles and suit distinct applications. Knowing their differences helps you select the best tool for your project.

Canvas isn’t the first material that comes to mind for engraving, but with the right tools and techniques, it’s entirely possible. Engraved canvas delivers a distinctive look for personalized gifts, décor, or signage, blending texture and artistry.

How Canvas Engraving Works

Specialized laser engravers can engrave canvas by removing the top layer of material without burning through it. Instead of carving, lasers gently etch the fibers to create a soft, textured design. Natural-fiber canvas, such as cotton or linen, engraves cleanly, while synthetic materials may melt rather than engrave well.

The result is a warm, organic finish that stands out beautifully in both rustic and modern décor. Engraved canvas is ideal for quotes, coordinates, logos, wedding gifts, and photographic elements that gain character from the fabric's natural grain.

Benefits of Engraving Canvas

Canvas engraving offers several advantages over printing or painting. The process integrates the design into the material itself, so it won’t peel, crack, or fade like surface-level inks. The engraved texture also gives each piece a handcrafted, high-end feel that mass-produced décor can’t replicate.

Canvas remains lightweight, versatile, and easy to display in homes, offices, or retail settings. Its subtle engraving aesthetic pairs well with wood frames, floating mounts, and minimalist interior styles.

Ready to Create a Custom Engraved Canvas?

If you’re looking for a one-of-a-kind gift or décor piece, White Dog Engraving, located in Dallas, brings expertise, precision, and creativity to every project. From custom artwork to personalized keepsakes, they can help you transform canvas into a meaningful engraved masterpiece.

Contact White Dog Engraving today and let us bring your custom canvas engraving project to life! Discover how your vision can become a stunning, personalized masterpiece—reach out now to get started.

Get an engraving quote today by fcalling us at (972)848-7790 or click here to connect with us online.

Understanding the Difference Between a Fiber Laser and a UV Laser

Fiber and UV lasers are leading technologies for marking, engraving, and cutting materials. Both offer high precision and efficiency, but operate on different principles and suit distinct applications. Knowing their differences helps you select the best tool for your project.

Fiber and UV lasers are leading technologies for marking, engraving, and cutting materials. Both offer high precision and efficiency, but operate on different principles and suit distinct applications. Knowing their differences helps you select the best tool for your project.

How Fiber Lasers Work

Fiber lasers use optical fibers doped with rare-earth elements, such as ytterbium, to generate a laser beam. The amplified light in the fiber core produces a focused beam at around 1064 nm in the infrared spectrum.

This wavelength interacts well with metals, making fiber lasers ideal for engraving and cutting metal surfaces such as stainless steel, aluminum, brass, and titanium. They also work on some plastics and ceramics that absorb infrared light.

Fiber lasers deliver speed, efficiency, and longevity. The beam travels through an optical fiber, creating a compact, low-maintenance setup. Their high efficiency and low costs make them popular in industrial uses such as:

Metal engraving and cutting

Marking serial numbers or barcodes on tools and components

Laser welding and micro-machining

However, fiber lasers are unsuitable for heat-sensitive materials or those that poorly absorb infrared light, such as glass or transparent plastics.

How UV Lasers Work

UV lasers operate at shorter wavelengths—about 355 nm—produced by harmonic generation, which converts infrared light to ultraviolet light.

UV lasers, or “cold lasers,” use this short wavelength for non-thermal marking and engraving. Instead of melting or burning, the UV beam breaks molecular bonds, producing fine, high-contrast marks with minimal heat impact.

These traits suit UV lasers for delicate or heat-sensitive materials, including:

Glass and quartz

Certain plastics (like ABS, PET, and PVC)

Silicone and ceramic materials

Medical devices, circuit boards, and microelectronics

Because UV lasers can mark nearly any material without distortion or discoloration, they are widely used in precision and cleanliness-sensitive fields, such as electronics, medical manufacturing, and aerospace.

Learn more about the engraving services that we can offer you by calling us at (972)848-7790 or click here to connect with us online.

Engraved Gift Ideas for the Holidays: Personalized Presents That Make a Lasting Impression

When the holidays arrive, finding the perfect gift is challenging. Everyone wants to give something meaningful that stands out among a sea of gift cards and mass-produced items. That’s where engraved gifts shine. Personalization turns an ordinary item into a keepsake with emotional value long after the wrapping paper is gone.

When the holidays arrive, finding the perfect gift is challenging. Everyone wants to give something meaningful that stands out among a sea of gift cards and mass-produced items. That’s where engraved gifts shine. Personalization turns an ordinary item into a keepsake with emotional value long after the wrapping paper is gone.

Why Choose Engraved Gifts?

Engraving adds a unique, thoughtful touch to any gift. Whether it’s a name, date, or message, personalization shows you put in extra effort. It transforms even simple items—like pens or frames—into memorable treasures. Engraved gifts suit family, friends, coworkers, or clients by combining practicality and sentiment.

Top Engraved Gift Ideas for the Holidays

1. Custom Jewelry

Necklaces, bracelets, and rings engraved with initials, names, or special dates make personal, stunning gifts. For parents, a pendant with children’s names or birthstones adds meaning. For couples, engraved coordinates or anniversary dates make lasting, romantic keepsakes.

2. Personalized Cutting Boards

For home chefs or entertainers, a laser-engraved cutting board with the family name or a favorite quote is decorative and useful. Pair it with gourmet cheese or wine for an elegant gift set.

3. Engraved Glassware

Custom wine glasses, whiskey tumblers, or beer mugs engraved with names, monograms, or festive designs are ideal for those who entertain. They’re great additions to holiday parties or housewarmings.

4. Photo Frames and Keepsake Boxes

Capture memories in an engraved frame or keepsake box. Add a personal message or important date to create an heirloom-worthy item. These are perfect for those who value sentimental gifts.

5. Personalized Office Accessories

Engraved pens, card holders, or desk nameplates make professional yet thoughtful gifts for coworkers, employees, or partners. They balance personal and practical, showing appreciation during the season.

6. Custom Ornaments

Engraved ornaments with names, initials, or the year are keepsakes enjoyed year after year. They’re meaningful, affordable, and ideal for friends, teachers, and neighbors.

Making the Gift Truly Special

Personalization is key to a perfectly engraved gift. Choose a meaningful message—a quote, special date, or simple 'Love Always.' Consider what will make the recipient smile each time they see it. Quality engraving ensures your message lasts as long as the memory.

Final Thoughts

This holiday, skip generic gifts and give from the heart. Engraved presents blend craftsmanship, beauty, and a personal touch, making them unforgettable. Whether it’s keepsake jewelry or a custom kitchen accessory, engraved gifts create lasting memories—a perfect way to share love and appreciation during the holidays.

Learn more about our engraving services by calling us (972)848-7790 at or click here to connect with us online.

Tips for Engraving Photos: How to Get the Best Results

Engraving photos onto wood, metal, or acrylic is a timeless way to preserve memories. Whether for gifts, memorials, or custom décor, perfect results require careful preparation and technique. Use these essential tips for success.

Engraving photos onto wood, metal, or acrylic is a timeless way to preserve memories. Whether for gifts, memorials, or custom décor, perfect results require careful preparation and technique. Use these essential tips for success.

1. Start with a High-Quality Image

Begin with a clear, high-resolution image. Choose photos with distinct lighting and contrast—faces should be defined, not shadowed. Avoid blurry or pixelated images, as flaws are visible when engraved.

2. Adjust the Contrast and Brightness

Use photo-editing software to adjust contrast and minimize background distractions before engraving. Ensure the subject stands out as the focal point.

3. Choose the Right Material

Materials yield different results. Wood offers a warm look; metal and acrylic provide sharp detail. Test a small section to check tone and grain compatibility.

4. Use Grayscale Conversion

Engravers can't reproduce color, so they convert photos to grayscale. Adjust shadows and highlights to improve balance.

5. Test Your Settings

Each machine and material varies. Test laser power, speed, and resolution on a sample before your final project.

With these tips, transform any photo into a lasting, beautifully engraved masterpiece—ideal for gifts, keepsakes, or décor.

Get an engraving quote today by calling us at (972)848-7790 or click here to connect with us online.

What’s New In Laser Engraving?

Traditionally, CO₂ lasers dominated large-scale engraving, especially for non-metals.

Traditionally, CO₂ lasers dominated large-scale engraving, especially for non-metals. Now, fiber lasers efficiently engrave metal, plastics, and some White Dog composites. They are becoming more affordable, popular, and capable. A finer beam diameter and lower heat-affected zone allow fiber lasers to achieve sharper details and cause less thermal damage.

Here are more new advancements in laser engraving.

Smarter Automation & AI Integration

Engraving machines are getting smarter. Artificial intelligence and machine learning now dynamically adjust parameters like speed, power, and focus for each material, or in response to variations in the material being engraved. Real-time monitoring, predictive maintenance, and IoT-enabled systems minimize waste and downtime.

Material Innovation & New Substrates

As demand rises for personalization and diverse applications, more professionals are engraving unconventional materials—smart materials, biodegradable or recycled substrates, ceramics, leather, and fabric are all being pushed further than before. Many machines now engrave curved or irregular surfaces.

Improved Hardware & Workflow Enhancements

Better cooling, finer optics, auto-focus, and flexible work areas enable faster engraving, less setup, and consistent quality. Improved material handling speeds up production in industrial settings.

Sustainability & Efficiency

Energy-efficient lasers and eco-friendly materials reduce costs and environmental impact. Businesses can now achieve high performance and sustainability.

Why It Matters

Advancements mean sharper, faster engraving, more material options, and greener operations. Shops and creatives can deliver complex designs, faster production, and improved margins.

Contact Us

If you’re looking for an engraving partner who’s keeping pace with these cutting-edge innovations, White Dog Engraving in Dallas, Texas is ready to bring your ideas to life. Whether you want crisp detail on metal, beautiful personalized designs on wood or leather, or fast turnaround on custom projects—our team uses the latest laser technologies to deliver top quality. Get in touch with us today, tell us what you need, and let White Dog Engraving show you what modern laser engraving can do for your business or project.

Dallas, Texas Engraving Company: Craftsmanship that Leaves a Lasting Impression

Personalized gifts, custom signage, and branded business products become unforgettable with expert engraving. For residents and businesses across North Texas, a Dallas, Texas engraving company offers the skill, technology, and precision needed to turn ordinary materials into memorable, one-of-a-kind pieces. Whether it’s a keepsake for a loved one or a professional branding project, engraving brings timeless beauty and lasting value to nearly any surface.

Personalized gifts, custom signage, and branded business products become unforgettable with expert engraving. For residents and businesses across North Texas, a Dallas, Texas engraving company offers the skill, technology, and precision needed to turn ordinary materials into memorable, one-of-a-kind pieces. Whether it’s a keepsake for a loved one or a professional branding project, engraving brings timeless beauty and lasting value to nearly any surface.

The Art and Science of Engraving

Engraving combines traditional artistry with modern innovation. Skilled technicians utilize tools such as laser engravers, rotary machines, and diamond-tipped instruments to etch intricate designs into various materials, including metal, glass, wood, leather, and more. The process removes a fine layer of material to create permanent markings—such as names, logos, dates, or intricate graphics—that won’t fade or wear away over time.

In Dallas, engraving companies often work with both individual clients and corporate customers. This flexibility enables them to produce a wide range of items, from elegant wedding gifts and trophies to commercial nameplates, industrial tags, and branded promotional products. The versatility of engraving makes it a top choice for anyone who values craftsmanship and precision.

Services Offered by Dallas Engraving Experts

A leading engraving company in Dallas, Texas, typically offers a wide range of services, including:

Laser Engraving: Ideal for intricate designs on materials such as stainless steel, acrylic, glass, or anodized aluminum. Laser engraving ensures precision and consistency for large batches or intricate patterns.

Custom Awards & Trophies: Dallas White Dog engravers often create personalized awards, plaques, and recognition pieces for events, schools, and sports teams.

Industrial Marking: Engraved labels, serial plates, and tags help businesses meet compliance and maintain a professional image.

Gifts and Keepsakes: Engraving makes jewelry, watches, cutting boards, and photo frames into lasting mementos.

Signage & Branding: Businesses use engraved signs and nameplates to convey professionalism and durability in offices or storefronts.

Each project receives precise attention, reflecting the client’s vision and the company’s commitment to quality.

Why Choose a Dallas Engraving Company?

Dallas is renowned for its quality craftsmanship and service, including expert engraving. Local companies blend experience with technology, offering fast turnarounds and precision. Whether you need a single gift or mass production, these experts deliver efficiently and artistically.

A local Dallas engraver offers personal consultation. Clients can view samples, discuss designs in person, and approve proofs before production. This ensures the final piece meets or exceeds expectations.

A Lasting Mark of Quality

In a world of mass production, engraving offers true personalization. A Dallas engraving company delivers craftsmanship that tells a story. Each piece showcases care, attention to detail, and artistry that is remembered for years.

Whether celebrating a milestone, enhancing your brand, or commemorating an occasion, the right Dallas engraver makes it unforgettable—one precise mark at a time.

Get an engraving quote for your business by calling us at (972)848-7790 or click here to connect with us online.

How Long Will My Engraving Project Take?

When planning an engraving project, one of the most common questions is: how long will it take? The answer depends on several key factors, including the material, design complexity, equipment used, and project volume.

The time required for an engraving project depends on the material, design complexity, equipment, and quantity.

1. Material Type

Softer materials, such as wood, acrylic, or leather, engrave quickly. Harder surfaces, such as glass, stone, or metal, require more time, especially when precision is needed.

2. Design Complexity

Simple text engraves in minutes. Detailed logos or fine artwork require more time, as machines must work more slowly to achieve precision.

3. Project Size and Quantity

A single small item may take under an hour. Bulk orders or large quantities may take longer, such as a day or more, for 100 items.

4. Equipment and Expertise

Modern lasers engrave faster. Experienced professionals optimize settings to minimize time and maintain quality.

Typical Turnaround Expectations

Small, simple jobs: same-day or within 24 hours

Moderate projects: 2–5 business days

Large, custom, or bulk orders: 1–2 weeks

Overall, project duration ranges from minutes to weeks, depending on material, design, and quantity. For an accurate estimate, provide your engraver with these details upfront.

Learn more about the engraving projects that we can offer you by calling us at (972)848-7790 or click here.

Laser Engraving Leather Debossing Stamps with MDF and Acrylic

Creating professional debossed designs is easier than ever with a laser engraver in Dallas, Texas. With MDF (medium-density fiberboard) or acrylic, you can create custom leather debossing stamps for crisp impressions on wallets, belts, and other items.

Creating professional debossed designs is easier than ever with a laser engraver in Dallas, Texas. With MDF (medium-density fiberboard) or acrylic, you can create custom leather debossing stamps for crisp impressions on wallets, belts, and other items.

Why Use MDF and Acrylic for Stamps?

MDF is a cost-effective material that works well for engraving intricate details. Its density allows for clean etching, making it a solid choice for hobbyists and small businesses experimenting with stamp creation. Acrylic, on the other hand, is durable and can withstand repeated use without losing White Dog detail. Many crafters prefer acrylic when producing higher-quality stamps designed for long-term use.

The Laser Engraving Process

A Dallas, Texas laser engraver can precisely cut and etch both MDF and acrylic into your desired stamp shape. The process typically involves:

Designing the Artwork – Use vector software to create your logo, text, or pattern. Bold, simple designs tend to stamp better into leather.

Selecting the Material – Choose MDF for affordability and practice runs, or acrylic for durability and sharper details.

Engraving and Cutting – The laser engraver etches the negative space of your design into the material, leaving a raised surface for debossing.

Stamp Mounting – Once engraved, the stamp can be mounted on a wooden block or metal press plate for ease of use.

Using Stamps on Leather

To create the debossed impression, leather should be slightly moistened before pressing. A heat press or hand-operated press applies steady pressure, allowing the engraved MDF or acrylic stamp to leave a permanent, professional-looking mark.

Benefits of Laser-Engraved Leather Stamps

Customization: Ideal for small businesses seeking to brand their products with logos.

Precision: Laser engraving ensures fine details are captured, even on small designs.

Cost-Effective: MDF and acrylic are more affordable than metal stamps.

Local Support: Working with a Dallas, Texas laser engraver provides easy access to custom services, quick turnaround times, and professional expertise.

Contact Us

Whether you’re experimenting with DIY leather projects or running a leather goods business, using MDF and acrylic to make debossing stamps is a smart way to achieve professional results. With the precision of a Dallas Texas laser engraver, you can create long-lasting, detailed stamps that elevate your craftsmanship.

Let’s talk about your engraving project! Contact us today by calling (972)848-7790 or click here to connect with us online.

How To Choose a Laser Cutter, Engraver, or Marker

Laser technology is vital for businesses and hobbyists. Selecting the right laser cutter, engraver, or marker ensures quality results. Consider these key factors when deciding.

Laser technology is vital for businesses and hobbyists. Selecting the right laser cutter, engraver, or marker ensures quality results. Consider these key factors when deciding.

1. Define Your Purpose

Start by identifying what you want to accomplish. A laser cutter is ideal for cutting through materials such as wood, acrylic, and fabric. A laser engraver creates detailed surface designs, while a laser marker is ideal for permanent, high-contrast markings on metals and plastics. Understanding your primary application will significantly narrow your options.

2. Consider Material Compatibility

Different lasers are more effective on specific materials. For example, CO₂ lasers excel with wood, glass, and acrylic, while fiber lasers are better suited for metals. If you need versatility, look for a system that supports multiple material types.

3. Evaluate Power and Speed

The wattage of a laser directly impacts cutting depth and speed. Higher-wattage machines handle thicker materials more efficiently, while lower-wattage models are better for fine engraving work. Balance power with precision depending on your needs.

4. Software and Ease of Use

User-friendly software is critical, especially if you’re new to laser technology. Look for systems with intuitive controls, design compatibility, and strong support communities.

5. Budget and Support

Prices vary widely depending on features and size. Beyond the initial cost, consider factors such as maintenance, replacement parts, and the availability of customer support. A reputable supplier with strong after-sales service can save you time and money long term.

By carefully assessing your goals, materials, and budget, you’ll be well-prepared to select the right laser system—ensuring efficiency, precision, and growth in your projects or business.

Learn more about the engraving services thatwe can offer you by calling us at (972)848-7790 or click here to connect with us online.

Tips for Laser Cutting Plastic: A Guide for Best Results

Laser cutting is one of the most precise and efficient methods for shaping plastics, whether for signage, product prototypes, or custom designs. However, working with plastic requires careful preparation to ensure clean, safe, and professional results. If you’re considering a project that involves engraving or fabrication in Dallas, Texas, here are some key tips for laser cutting plastic.

Laser cutting is one of the most precise and efficient methods for shaping plastics, whether for signage, product prototypes, or custom designs. However, working with plastic requires careful preparation to ensure clean, safe, and professional results. If you’re considering a project that involves engraving or fabrication in Dallas, Texas, here are some key tips for laser cutting plastic.

1. Choose the Right Plastic Type

Not all plastics are created equal. Acrylic is the most common material for laser cutting because it produces smooth, polished edges and handles engraving well. Polycarbonate, on the other hand, should be avoided as it discolors and emits harmful fumes. Always confirm the material’s compatibility with laser equipment before cutting.

2. Adjust Laser Settings Properly

Power, speed, and frequency are critical White Dog settings that determine the quality of your cut. Too much power can melt edges, while too little may leave incomplete cuts. It’s best to run test samples to fine-tune settings for your specific type of plastic.

3. Minimize Heat Build-Up

Plastics are sensitive to heat, which can cause warping or burning. Using air assist during cutting helps blow away heat and debris, keeping edges clean and preventing damage.

4. Keep Safety in Mind

Laser cutting produces fumes when working with plastics. Proper ventilation or a fume extraction system is essential for a safe workspace.

5. Work with Professionals

For intricate designs or large projects, partnering with an experienced shop that offers laser cutting and engraving services in Dallas, Texas, ensures your work is accurate, polished, and handled safely.

By following these tips, you’ll achieve sharp, clean cuts while protecting both your project and your equipment. Laser cutting plastic can be an excellent choice when done with the right materials and settings.

Get a laser engraving quote by calling us at (972)848-7790 or click here to connect with us online.

Top Ideas for Wine Bottle Engraving at Oktoberfest

Oktoberfest is often celebrated with beer steins, pretzels, and festive music, but wine has also become an increasingly popular feature of the season. Personalized wine bottles offer a unique way to commemorate the event, and engraving adds an elegant, lasting touch.

Oktoberfest is often celebrated with beer steins, pretzels, and festive music, but wine has also become an increasingly popular feature of the season. Personalized wine bottles offer a unique way to commemorate the event, and engraving adds an elegant, lasting touch. Whether you are a business seeking promotional opportunities or an individual looking for a memorable keepsake, engraved wine bottles at Oktoberfest make a lasting impression. Here are some top ideas for wine bottle engraving during the festivities.

1. Event Logos and Dates

Engraving the official Oktoberfest logo or the year of the celebration on a wine bottle transforms it into a collectible. This approach is especially appealing for guests who want a souvenir to mark their visit. Businesses can also customize bottles with local festival logos to connect their brand with the festive spirit.

2. Traditional Bavarian Motifs

Images such as pretzels, beer mugs, alpine hats, or edelweiss flowers engraved on wine bottles add a cultural touch. These motifs bring the Bavarian heritage to life and can be paired with text for a fully customized design. Using symbolic elements of the festival enhances the celebratory feel of the bottles.

3. Personalized Names and Messages

For private gatherings or corporate events during Oktoberfest, adding engraved names or short messages makes the bottles stand out. A phrase like “Prost, Anna!” or “Cheers from Munich 2025” turns a standard bottle of wine into a memorable gift. This type of personalization is well-suited for hosts who want to give their guests meaningful mementos.

4. Corporate Branding

Many companies use Oktoberfest as a networking opportunity. Custom-engraved wine bottles with a company logo and tagline serve as premium promotional gifts. They not only highlight the brand but also align it with the festive and convivial atmosphere of Oktoberfest.

5. Commemorative Artwork

Limited-edition artwork can be engraved onto wine White Dog bottles to create collector’s items. Local landmarks, festival tents, or Oktoberfest-inspired illustrations work particularly well. These engraved designs appeal to both tourists and locals who value tradition and artistry.

Conclusion

Engraved wine bottles bring elegance and individuality to Oktoberfest celebrations. From logos and Bavarian motifs to personalized messages and artwork, the options are versatile and memorable. Whether used for personal keepsakes or corporate gifts, custom engraving ensures that each bottle serves as a lasting reminder of the season’s festivities. Take the next step and create your own unforgettable Oktoberfest keepsake or branded gift today.

Recommendation: When promoting engraved wine bottles, emphasize the celebration of Bavarian culture, the possibilities for personalization, and the branding opportunities that this presents. Encourage customers to design or order their engraved bottles now to stand out during Oktoberfest.

Next step: Begin developing engraving templates that blend Oktoberfest symbols with space for custom text. Invite interested customers to reach out or collaborate on custom designs to make their bottles truly unique and memorable.

Get an engraving quote today by calling us at (972) 848-7790 or click here to connect with us online.

5W vs 10W ComMarker Omni 1 UV Laser: Which One Is Right for You?

When it comes to laser engraving, precision and efficiency matter. The ComMarker Omni 1 UV Laser series is renowned for its ability to engrave a wide range of materials, including plastics, glass, metals, and even delicate substrates. But if you’re considering investing in this technology, one key decision is whether the 5W or 10W version is the better choice.

When it comes to laser engraving, precision and efficiency matter. The ComMarker Omni 1 UV Laser series is renowned for its ability to engrave a wide range of materials, including plastics, glass, metals, and even delicate substrates. But if you’re considering investing in this technology, one key decision is whether the 5W or 10W version is the better choice.

The 5W ComMarker Omni 1 UV Laser

The 5W model is an excellent entry-level option for businesses and hobbyists who require detailed, high-contrast marking without excessive power consumption. Its lower wattage means less heat, making it ideal for materials that are sensitive to burning, such as plastics or coated surfaces. If your projects involve intricate logos, barcodes, or fine text, the 5W unit provides clean and crisp results with minimal risk of surface damage.

The 10W ComMarker Omni 1 UV Laser

The 10W version delivers more power, resulting in faster engraving speeds and deeper marks. It’s a better fit for high-volume production environments where time is of the essence. The extra wattage also allows for engraving tougher materials, such as certain metals or thicker plastics, with greater efficiency. However, with the increased power comes a higher price point, which may not be practical for smaller-scale operations.

Which One Is Right for You?

The choice between the 5W and 10W ComMarker Omni 1 UV Laser depends largely on your application and budget. If you require precise measurements, the 5W is sufficient. If you’re focused on speed, durability, and handling larger production runs, the 10W is the smarter investment.

But here’s the reality—purchasing and maintaining either machine requires a significant upfront cost and ongoing technical know-how. For many businesses, especially small to mid-sized companies, outsourcing laser engraving to a local engraving company like White Dog Engraving is the more cost-effective option.

Save Time and Money with Local Expertise

Instead of spending thousands on equipment and training, you can achieve the same high-quality results by working with professionals who already have the latest UV laser technology. We can handle your custom jobs quickly, eliminate the learning curve, and save you the headache of equipment maintenance.

If you want precision, speed, and cost savings without the investment, contact us today! You’ll start benefiting from 5W or 10W laser engraving without the expense, saving both time and money while gaining expert results.

Get an engraving quote today by calling us at (972) 848-7790 or click here to connect with us online.