How To Choose a Laser Cutter, Engraver, or Marker

Laser technology is vital for businesses and hobbyists. Selecting the right laser cutter, engraver, or marker ensures quality results. Consider these key factors when deciding.

Laser technology is vital for businesses and hobbyists. Selecting the right laser cutter, engraver, or marker ensures quality results. Consider these key factors when deciding.

1. Define Your Purpose

Start by identifying what you want to accomplish. A laser cutter is ideal for cutting through materials such as wood, acrylic, and fabric. A laser engraver creates detailed surface designs, while a laser marker is ideal for permanent, high-contrast markings on metals and plastics. Understanding your primary application will significantly narrow your options.

2. Consider Material Compatibility

Different lasers are more effective on specific materials. For example, CO₂ lasers excel with wood, glass, and acrylic, while fiber lasers are better suited for metals. If you need versatility, look for a system that supports multiple material types.

3. Evaluate Power and Speed

The wattage of a laser directly impacts cutting depth and speed. Higher-wattage machines handle thicker materials more efficiently, while lower-wattage models are better for fine engraving work. Balance power with precision depending on your needs.

4. Software and Ease of Use

User-friendly software is critical, especially if you’re new to laser technology. Look for systems with intuitive controls, design compatibility, and strong support communities.

5. Budget and Support

Prices vary widely depending on features and size. Beyond the initial cost, consider factors such as maintenance, replacement parts, and the availability of customer support. A reputable supplier with strong after-sales service can save you time and money long term.

By carefully assessing your goals, materials, and budget, you’ll be well-prepared to select the right laser system—ensuring efficiency, precision, and growth in your projects or business.

Learn more about the engraving services thatwe can offer you by calling us at (972)848-7790 or click here to connect with us online.

What Is Laser Engraving?

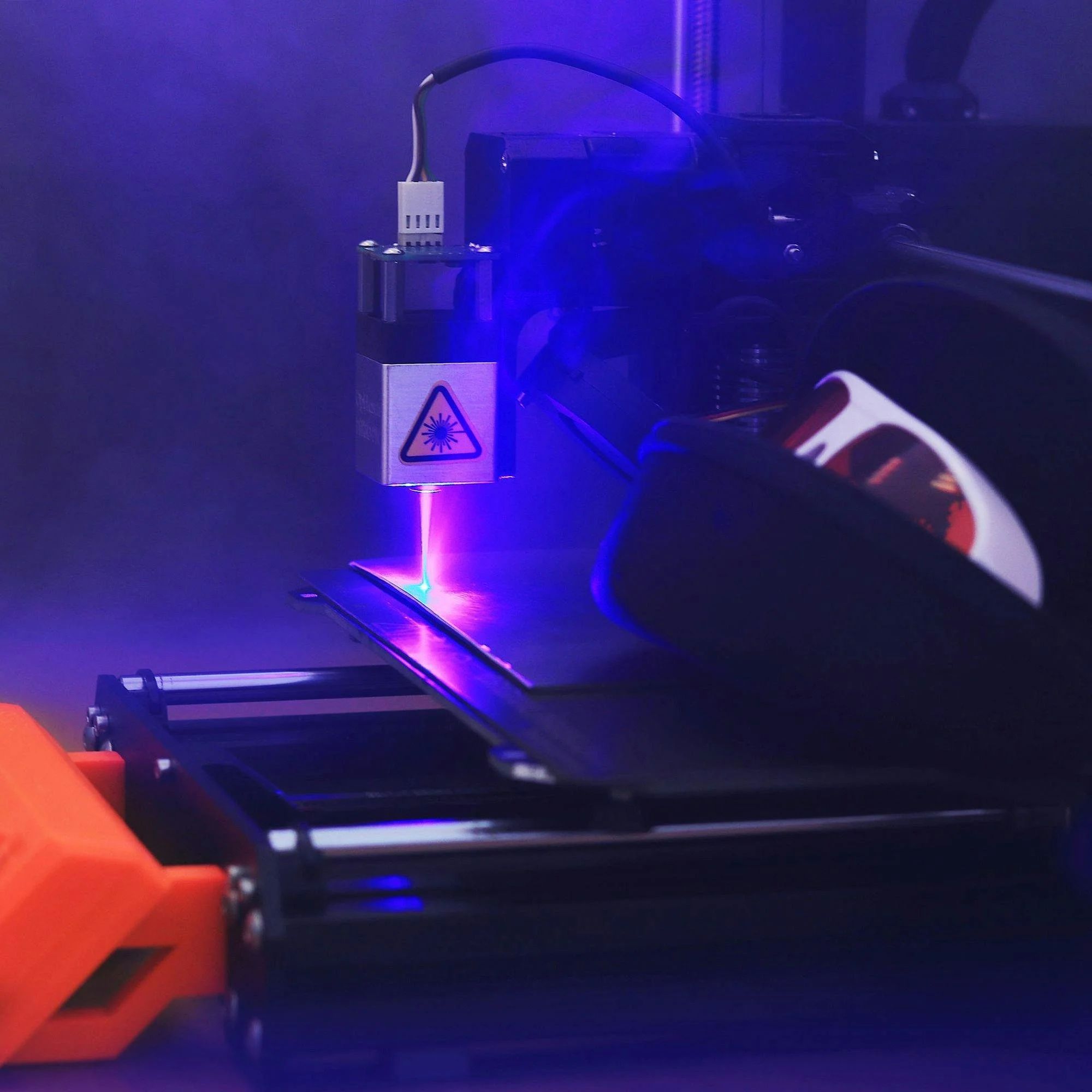

Laser engraving is a modern and precise method of etching or marking the surface of an object using a focused beam of light. This process removes material from the surface to create a permanent design, text, or image. It’s widely used in industries ranging from manufacturing and electronics to jewelry and arts due to its accuracy, durability, and versatility.

Laser engraving is a modern and precise method of etching or marking the surface of an object using a focused beam of light. This process removes material from the surface to create a permanent design, text, or image. It’s widely used in industries ranging from manufacturing and electronics to jewelry and arts due to its accuracy, durability, and versatility.

At its core, laser engraving involves a high-powered laser beam directed at a material. This beam generates intense heat, which vaporizes the surface layer of the material, leaving behind a visible mark. Unlike traditional engraving methods that use sharp tools to physically cut into a surface, laser engraving is non-contact. This means there’s no direct mechanical pressure on the item, which minimizes the risk of damage or distortion.

About Laser Engraving

Laser engraving is often confused with laser etching and laser marking. While these terms are sometimes used interchangeably, they represent slightly different processes. Laser etching melts the surface of the material rather than vaporizing it, creating a raised mark. Laser marking, on the other hand, changes the color of the material without removing any surface. Among these, laser engraving is the most aggressive in terms of depth and permanence.

One of the key benefits of laser engraving is its ability to produce highly detailed and intricate designs. The laser can be precisely controlled by computer software, allowing for the creation of custom images, barcodes, logos, and even photographs. This level of detail makes it ideal for applications like personalized gifts, industrial labeling, and creating fine art.

Materials compatible with laser engraving include wood, metal, glass, acrylic, leather, stone, and certain plastics. The choice of laser—such as CO₂, fiber, or diode—depends on the material being engraved. For instance, CO₂ lasers are commonly used for wood, glass, and leather, while fiber lasers are more suitable for metals and printed plastics.

In addition to being precise, laser engraving is also fast and efficient. Once a design is programmed into the system, the laser can reproduce the same pattern repeatedly with consistent quality. This makes it a popular choice for mass production as well as one-off custom jobs.

Safety is also an important consideration. While laser engravers are generally safe when used properly, the process does involve intense light and potentially harmful fumes, depending on the material. Proper ventilation, safety enclosures, and eye protection are recommended when operating laser engraving equipment.

Superior Precision

In summary, laser engraving is a high-tech method of permanently marking or decorating a wide range of materials using a laser beam. It offers superior precision, versatility, and repeatability compared to traditional engraving methods. Whether for commercial use, artistic expression, or personal customization, laser engraving has become a go-to technology for creating lasting impressions.

Learn more about the laser engraving services that we can offer you by clicking here to connect with us online.

Why Choose A Laser Engraver?

Choosing the right laser engraver for your needs can be a game-changer, whether you're a small business owner, a hobbyist, or an artist. With so many models and features available, selecting the right one involves a balance of understanding your requirements and evaluating the options available. Here's a comprehensive guide to help you make an informed decision.

Choosing the suitable laser engraver for your needs can be a game-changer, whether you're a small business owner, a hobbyist, or an artist. With so many models and features available, selecting the right one involves balancing understanding your requirements and evaluating the options available.

Understanding Your Needs

Before diving into the specifics of laser engravers, you must clearly understand what you want to achieve. Ask yourself:

What Materials Will You Engrave? Different laser engravers handle various materials like wood, acrylic, glass, metal, and leather. If you plan to work with multiple materials, look for a versatile machine that offers compatibility with a broad range of substrates.

What Size Projects Will You Undertake? Consider the size of the items you'll be engraving. Laser engravers come in different sizes, from compact desktop models suitable for small projects to larger machines capable of handling big pieces.

What is Your Budget? Laser engravers vary widely in price. Entry-level models cost a few hundred dollars, while advanced machines with high precision and additional features cost several thousand. Set a budget that aligns with your needs and long-term goals.

What Level of Precision Do You Require? Precision is critical, especially for detailed or intricate designs. Higher-end models generally offer better resolution and finer details.

Key Features to Consider

Once you've established your needs, evaluate laser engravers based on the following key features:

Laser Type: Two lasers are primarily used in engravers: CO2 and fiber. CO2 lasers are excellent for non-metallic materials such as wood, acrylic, and glass. Fiber lasers, on the other hand, are more suited for metal engraving and are known for their durability and speed.

Power Output: The laser's power affects the engraving's speed and depth. A lower-power laser (e.g., 30-40 watts) may suffice for lighter materials. For thicker or denser materials, you might need a more powerful laser (e.g., 60-100 watts).

Engraving Area: The work area size is crucial, especially if you plan to work on more oversized items or multiple items simultaneously. Ensure the engraving area accommodates your typical project sizes.

Software Compatibility: Check what design software is compatible with the laser engraver. Most machines come with proprietary software, but it's beneficial if it supports popular programs like Adobe Illustrator or CorelDRAW.

Ease of Use: Some laser engravers have advanced features like automatic focus and easy-to-use interfaces, while others may require more manual adjustments. Choose a model that matches your technical expertise and comfort level.

Build Quality and Durability: Invest in a well-built machine with longevity and reliability.

Support and Warranty: Ensure the manufacturer provides good customer support and a reasonable warranty period.

Contact White Dog Engraving

For more information about the DFW engraving services that we can offer you, contact us today by calling (972) 848-7790 or click here to connect with us online.